Oak framed houses in Cornwall and Devon

We've just finished raising this large oak framed house on the western edges of Dartmoor. It's an interesting build, something of a hybrid in the way that oak, masonry and steel are used together, but it actually makes perfect sense...using the right materials in the right area with regard to purpose, budget and aesthetic. The site is cut right into a steep slope, with a massively engineered 4m retaining wall holding the bank in place, so the rear wall of the house is a standard cavity block work wall. The focus of the property looks away from this, through a largely glazed western elevation, and out across fine views towards Brentor Church.

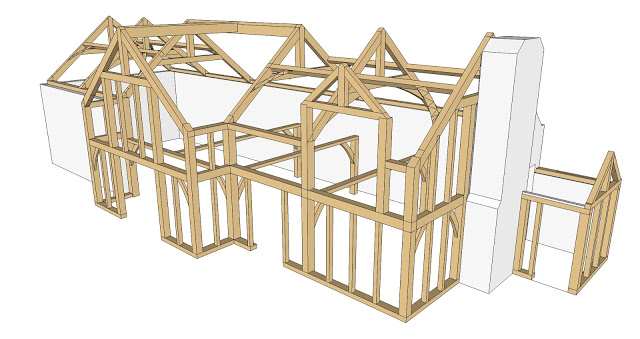

Being cut into a steep slope in this way makes getting a good photograph pretty tricky; you're either way above or way below the frame, and short of having photos taken from a drone, an image from the CAD program probably gives the best overall impression of this project. It's among the largest of the oak frames we've designed and built; although I had an architects proposal to work from, a large part of the general construction detailing came from our end. You can't effectively design and build an oak frame without careful attention to everything that interfaces with it, and I'm really pleased with how this one came out.

There's a nice cyclical story to the next large project we're undertaking. One of the first large oak framed buildings I worked on was the 4 bay barn/workshop shown below, built for Kimpton Moore near Camborne. Jamie Lovekin and I cut and raised the frame in 2004, and this was probably the first project that I really started to understand the complete process of traditional oak framing rather than just following Jamie's instructions.

Kimpton now runs

and has asked us to build the frame for the house that he and his wife have been patiently planning for several years. Lizard based Architect

has made a fine job of frame design and architectural detailing, and has constructed this 3D model to assist with the visualisation.

Kim himself is milling the English oak that we'll use to build the frame. Not many of our customers are in the position to be able to mill the timber for their own house, but Kim is ideally poised with his contacts in the industry to source and saw the 23 cubic metres of green oak needed for this project. We're about a third of the way through this already, and will need to stick to the schedule...the workshop diary is fairly full right through the summer, and I'm always mindful of the knock-on effects of falling behind with a project. Aiming for a raising in the second half of June, photos to follow once it's up!